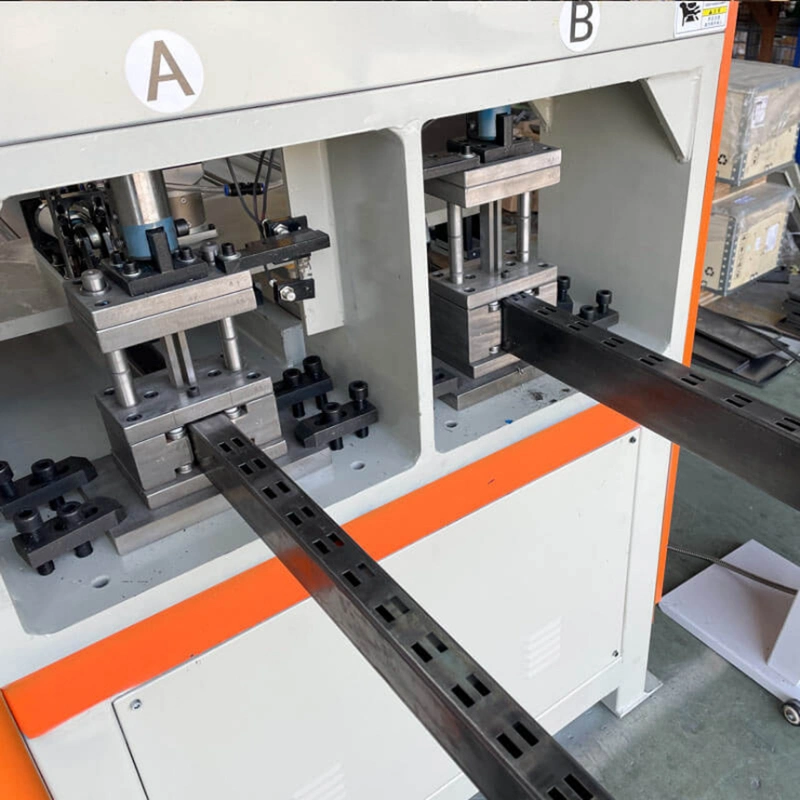

Punching Machine Aluminum Window Door Profile Portable Hydraulic Punching Machine Pneumatic Punching Machine

Overview Package Size 6200.00cm * 1500.00cm * 1200.00cm Package Gross Weight 3000.000kg CNC Hydraulic Pipe Tube Hole Pun

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Punch Shape | Open Punch |

| Slider Movement | Double Action |

| Slider Drive Mechanism | Hydraulic Pump |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Power Source | Hydraulic Pressure |

| Precision | High Precision |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Key Selling Points | High Productivity |

| Punching Speed | 70-120 Times/Min |

| CNC or Not | CNC |

| Usage | Tube Pipe Punching |

| Nominal Force | 250, 400, 600kn or Customized |

| Machine Type | Punching Machine |

| Motor Power | 7.5kw |

| Voltage | 380V or Customized |

| Capacity | 5--100 Ton |

| Transport Package | Professional Wooden Box |

| Specification | 6m Length |

| Origin | China |

| HS Code | 8462411900 |

| Production Capacity | 1500sets/Year |

Packaging & Delivery

Package Size 6200.00cm * 1500.00cm * 1200.00cm Package Gross Weight 3000.000kgProduct Description

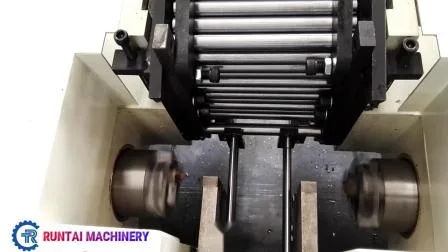

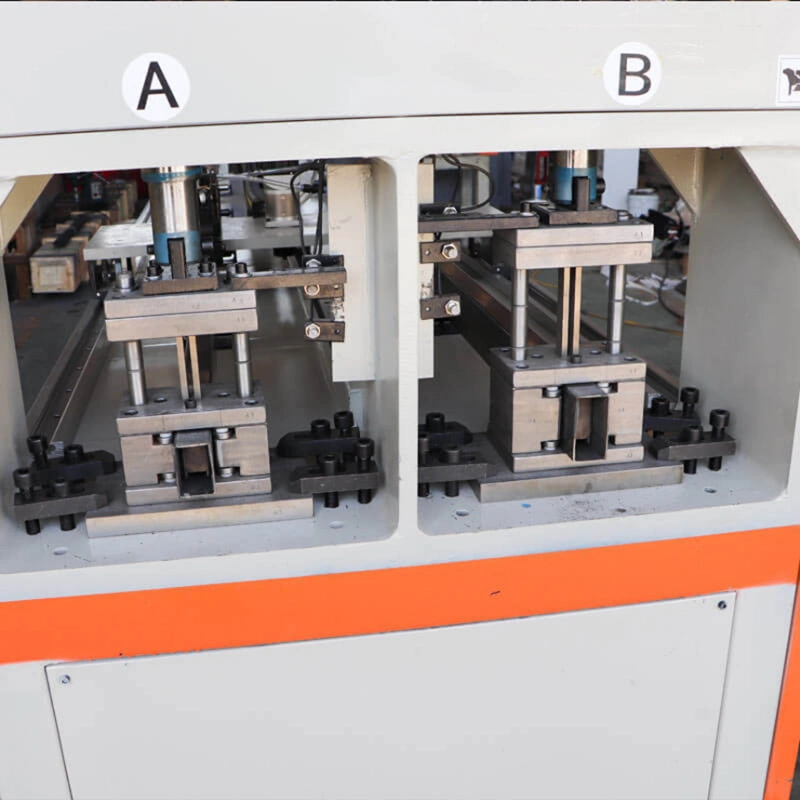

CNC Hydraulic Pipe Tube Hole Punching Machine CE ISO Certified

Advantages of the machine

a. The human-machine interface display, Touch Screen settings, NC control system, precise servo motor positioning, module storage memory function.

b. Structure:Steel plate welded structure

c. Mould replacement: change the die easily without adjusting the dies to reduce the mould damage rate and pipe fittings rejection rate due to the dies setting error. Skilled workers can change the mould within 10 minutes.

d. Punching Category: 1.single hole punching; 2.double hole punching; 3.Isometric hole punching; 4. none- Isometric hole punching; rotary punching.

e. Hydraulic and Servo System:

1. Step-less operation adjustment, hydraulic loops designed with zero load, combined with extremely low frequency oil pump motor, effectively reduced noise, increased motor efficiency and service duration.

2. When the oil cylinder is moving downward, the machine is designed with hydraulic difference driving loops rated at high or low RPM .it is also featured with high speed downward moving, low speed processing and hi-speed position resume .it is available to increase the formation stability of work pieces during puncturing .in addition to increasing the activation speed, it can effectively reduce HP load to save electrical energy.

3. The electrical control system is designed with the human machine interface, range adjustment use digital scale, setting low speed position, floor level position, and operation precise and easy.

4. Cylinder stroke 130mm (can be set), throat depth 300mm,available for forward and backward 150mm moving accessibility. Designed with the Italy-made digital scale with high precision.

| 1 | Model | 10--60 Ton | |

| 2 | Punching thickness | Τ0.5~τ11mm | |

| 3 | Hole | round pipe | Φ16~Φ120 mm |

| Square tube | 20×20~150×150 mm | ||

| rectangle pipe | 15×30~60×150 mm | ||

| Angle iron | 30×30~75×75mm | ||

| channel iron | 25×50~60×120mm | ||

| 4 | Hole distance | CNC control | |

| 5 | Punching speed | 70-120 Times/Min | |

| 6 | Longest distance between holes | CNC control | |

| 7 | Standard length | customized | |

| 8 | Main Motor Power | 7.5Kw | |

| 9 | Engineering Motion Classification | 1.Single puncturing operation | |

| 2.Irregular interval puncturing | |||

| 3.Regular interval puncturing | |||

| 4.360°rotating puncturing | |||

| 10 | TFT human machine interface | Human machine interface | |

| 11 | control system | touch controllable display setting ,Chinese and English exchange | |

| 12 | Memory Function | can be stored and memorized 0-99 groups processing mode | |

| 13 | Overall Dimension | 6300×1500×1700mm | |

| 14 | Weight | 3000Kg | |

Machine Application

FAQ

1. Q: What is the power supply of the machine? A: The standard power is 380V, 3P, 50Hz or customized by requirement.2. Q: What information should the customer provide to get an accurate quotation from us? A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc 3. Q: What is the payment termA: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 20 days after receive down payment. 5. Q: What is the warrantee period of the machine?

A: The warrantee period is 2 years since the date of B/L.

Related Products

-

![XL8145 High Precision Conventional Vertical Horizontal Universal Drilling Milling Machine]()

XL8145 High Precision Conventional Vertical Horizontal Universal Drilling Milling Machine

-

![Runtai Machinery Factory Model Rt]()

Runtai Machinery Factory Model Rt

-

![Dminingwell Used 600m Truck Mounted Deep Borehole Water Well Drilling Rig Machine for Sale]()

Dminingwell Used 600m Truck Mounted Deep Borehole Water Well Drilling Rig Machine for Sale

-

![New Disel Mini Dump Truck/Mini Wheel Dumper Mine Tipper Truck/China Mining Dump Truck Wheel Tippernew Design Garden Mini Dumper for Sale/4 Wheel Electric Cart]()

New Disel Mini Dump Truck/Mini Wheel Dumper Mine Tipper Truck/China Mining Dump Truck Wheel Tippernew Design Garden Mini Dumper for Sale/4 Wheel Electric Cart