Hydraulic Sheet Metal Steel Plate Beveling End Edge Milling Machine Groove Chamfering

Overview Package Size 2300.00cm * 600.00cm * 300.00cm Package Gross Weight 23000.000kg A. Usage and Application:1. This

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | XBJ and SXBJ-3~ 18 |

| Style | Desktop |

| Layout | Horizontal |

| Automatic Grade | Automatic |

| Power Source | Hydraulic |

| Certification | CE, ISO |

| Milling Depth Control | Ammeter on Milling Head |

| Workpiece Thickness | 6mm to 200mm |

| Milling Angle Control | Motor Drive, HMI Control, Angle Ruler |

| Advantage | Long Edge Milling Stroke, High Speed |

| Size | Medium and Heavy Duty, Large Size |

| Milling Angle Range | 0~ 85 Degree Edge Milling |

| Milling Head Quantity | 1/ 2/ 4 Sets |

| Workpiece Clamping | Hydraulic Drive Jacks |

| Workpiece Loading | Automatic Hydraulic Drive Rolling Rollers |

| Function | Metal Steel Plate Edge Milling Beveling |

| Working Element | 7.5/ 9/ 11kw Milling Head |

| Transport Package | Disassembled Into Wooden Case |

| Specification | 28 length, 6m width, 3m height |

| Trademark | Wuxi JACK and AMASS |

| Origin | Wuxi, China |

Packaging & Delivery

Package Size 2300.00cm * 600.00cm * 300.00cm Package Gross Weight 23000.000kgProduct Description

A. Usage and Application:1. This machine is for high efficiency beveling on various metal plates, especially carbon steel, for making welding groove;2. The metal plates cover full range of: 1) Length 3000 mm~ 18000 mm;2) Thickness 6mm ~ 200mm;3) Straight/ Top/ Bottom edges of grooves can be machined: (Fig.1,2)

B. Advantages of Wuxi JACK (Wuxi AMASS) Edge Milling Machine:

This is superior product of Wuxi JACK (Wuxi AMASS). Below slides give graphical explanation on our superiorities:

C. Categories and Main Specifications:

1. There are 2 Categories of Edge Milling Machine: 1) XBJ series single milling head; (Fig.3)

2) SXBJ series double milling heads;(Fig.4)

2. Milling angle: 1) 0°~ 45° for conventional angle groove: (Fig.5)

2) Special made 0°~ 85° milling head: (Fig.6)

3. Edge Milling Thickness: 1) Conventional models: 6mm~ 80mm; 2) Special made: 6mm~ 200mm. D. Main Units:

One set of Edge Milling Machine is mainly composed of:1) Mechanical system;2) Hydraulic driving system;3) Control system;4) Machine edge milling tool: Milling head, facer blade, its elevation, swing, feeding forward and backward driving motors, traveling carriage.

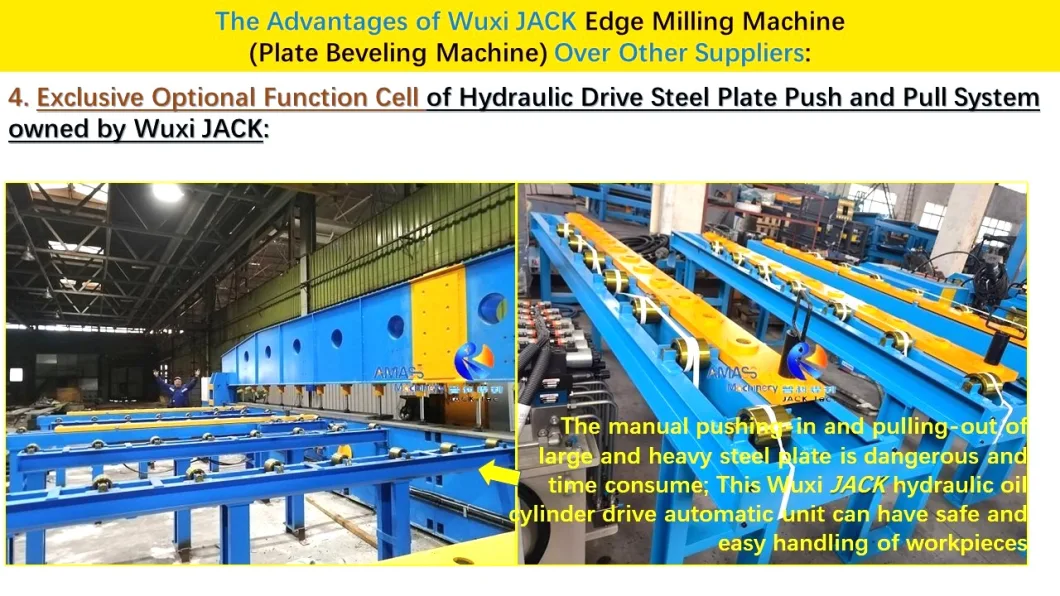

E. Unique Optional Useful Function Units of Wuxi JACK (Wuxi AMASS) Edge Milling Machine:1. Hydraulic Drive Metal Plate Pushing In and Loading Out System:(Fig.7)

2. HMI Touch Screen Precisely Controlling Milling Angle: (Fig.8)

F. Technical Parameters:

| Model Technical parameter | Diverse Type and Dimension XBJ and SXBJ Series Plate Edge Milling Machine (Plate Beveling Machine) |

| Max. Plate Edge Milling Length | 3000 mm~18000 mm for Conventional models;Special made parameters are available |

| Edge Milling Thickness | 6mm ~ 40/ 80 mm for Conventional models;6mm ~ 160mm for Special made |

| Workpiece Max. Weight | Up to 70s Ton |

| Power and rpm of Lengthways Milling Head | 7.5kW for conventional model, 9.3kW/ 11kW for heavy duty |

| Spindle rpm of Edge Milling Head | 65 ~ 715 r/min., 6/ 9 grades by handwheel |

| Milling Head Quantity | 1 or 2 sets (Single Head and Double Heads) |

| Milling Angle of Top Milling unit | 0° to +45° /+85° |

| Milling Angle of Down Milling unit | -45° to 0° |

| Lengthways Edge Milling Speed | Continuous (150~ 3000) mm/min. Inverter control |

| Idle High Speed of Milling Head | 4000 mm/min. |

| Quantity of Hydraulic Jacks | 6 ~ 39 pieces, depending on stroke |

Our AdvantagesAfter Sales ServiceFAQ1. Q: What is the relationship between Wuxi AMASS and Wuxi JACK?

A: Wuxi AMASS and Wuxi JACK are the same company: Wuxi AMASS is wholly owned subsidiary of Wuxi JACK, for overseas trading Wuxi JACK products;

2. Q: What is the nature of your company?

A: Business scope of Wuxi JACK and AMASS covers design, production and selling;

3. Q: What is the range of your company product?

A: Wuxi JACK and AMASS is a professional supplier in Welding and Cutting Industry;Main products of our company include:1) Steel structure production equipment (H Beam/ BOX Beam/ T Beam);2) Edge Milling Machine;3) Structure member Beam end face milling machine;4) CNC Plate Cutting Machine;5) CNC Pipe Cutting Machine;6) Various kinds of conventional and special design welding equipment and machine;7) Various kinds of conventional and special design Straightening machine, etc.;

4. Q: What is the strength of your company?

A:1) Wuxi JACK was founded by 3 senior engineers 15 years ago;2) Engineering team of our company has over 20 years experience on Welding and Cutting industry;3) Operation manager has 14 years experience working in an American Fortune Global 500 Dow Jones Industrial Index Company as senior Project Manager;4) The competitive edge of our company is special design products based on customer demand.

5. Q: What are service terms of your company?

A:1) During business negation: a) Make technical proposal and quotation;b) Answering customer questions;c) Make final contract and technical agreement;2) During order to delivery value chain:a) Design, validate, and manufacture products for customers;b) Inform progress of manufacture to customers;c) Arrangement for package and shipment of products to customers;3) After sale service: a) Technical support on installation and commissioning at customer site;b) 1 year guarantee from the date of acceptance;c) Feedback any technical issues within 4 hours upon getting the notice;

6. Q: Where is location of your company?

A: Wuxi city, Jiangsu province, 130km from Shanghai

Related Products

-

![Pipe Beveling Machine, CNC Pipe/End Groove/Chamfering Machine]()

Pipe Beveling Machine, CNC Pipe/End Groove/Chamfering Machine

-

![New Disel Mini Dump Truck/Mini Wheel Dumper Mine Tipper Truck/China Mining Dump Truck Wheel Tippernew Design Garden Mini Dumper for Sale/4 Wheel Electric Cart]()

New Disel Mini Dump Truck/Mini Wheel Dumper Mine Tipper Truck/China Mining Dump Truck Wheel Tippernew Design Garden Mini Dumper for Sale/4 Wheel Electric Cart

-

![China Kit Electric Wheelbarrow Electric Dump Cart for Garden 3 Wheeled Power Wheelbarrow 1000 Kg]()

China Kit Electric Wheelbarrow Electric Dump Cart for Garden 3 Wheeled Power Wheelbarrow 1000 Kg

-

![Easy Operating Drill Bit Sharpening Machines ED]()

Easy Operating Drill Bit Sharpening Machines ED